Own production

Fabricados TIR, meticulously takes care of the production process applying the highest technology, adding rigorous quality controls, made by qualified personnel, so that our customers only take care of the most important part: Enjoy our Windows.

Selection of raw materials

We acquire wood directly from sawmills in origin, rigorously selecting those that meet the most stringent quality standards.

Drying and storage

Of the quality of the drying, it depends to a great extent the life and future conservation of the wood. Before manufacture, the wood passes through a rigorous quality control: humidity, knots, mesh lines, etc.

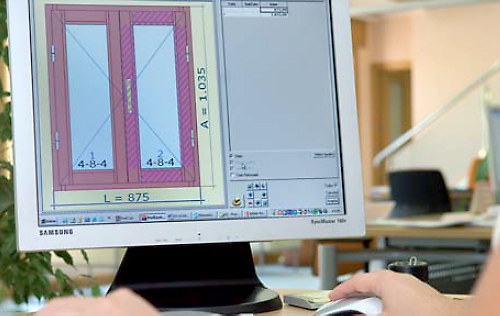

DESIGN AND START OF MANUFACTURING

Staff with specific management systems adapts the design chosen by our customers before starting manufacturing.

Our high-tech machinery is adapted to a wide variety of design possibilities for our products: straight models, curved, modern lines, etc.

MOUNTING

The Assembly and assembly are made with automatic presses, using products of high resistance and anti-humidity factor. Careful sanding will be the key to excellent varnishing and finishing.

Varnished

The stages of the process are as follows:

1.- Initial raw sandpaper for pore opening and defect removal.

2.- AUTOCLAVE Treatment:

- Phase of introduction of the wood and application of an initial vacuum, by means of which it is possible to open the pore of the wood, to eliminate the moisture and impurities.

- Spraying phase of the impregnating – fungicide with constant vacuum saturated inside the autoclave. (Nebulization – 1st hand)

- Phase of spraying with downward vacuum, entering the air in the autoclave that drags the product, helping it to penetrate in depth in the pores of the wood.

- Phase of evacuation of the impregnating and alternative vacuum inside the AUTOCLAVE, to facilitate the drying and draining of the treated parts.

3.- Immersion background application, widely used method worldwide.

4.-Fine finish sandpaper.

5.- Spray finish by AIR-MIX system.

HARDWARE

The hardware of each window is analyzed and exploded through a powerful software that guarantees its correct load capacity and durability. Hardware orders follow a “just In Time” process, with specific orders for each manufacturing order, without going through warehouse. Once the hardware and sealing joints have been fitted, the opening is adjusted and the quality of this is checked.

GLAZING AND SEALING

The glazing in our facilities allows us to offer the maximum guarantee of transparency in the window panes. Each glass is cleaned and checked to verify its quality and absence of scratches or interior stains.

FABRICADOS TIR uses 2 neutral silicone cords in the sealing, one rope for the settlement and one for the enclosure.

PACKING AND TRANSPORTATION

Each window is carefully protected during transport and transfer on site. Applying if necessary the shrink with extensible film.